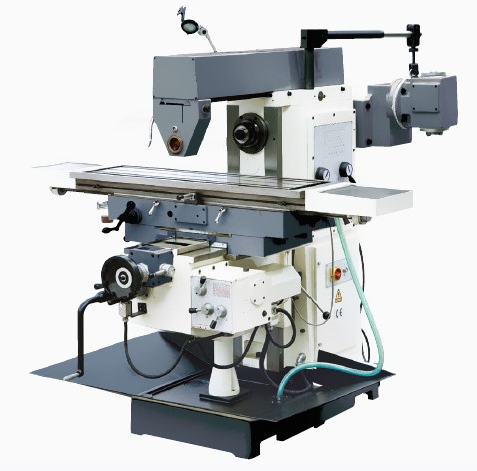

VMC850 CNC Vertical Milling makina

Mafotokozedwe Akatundu

2. Kokani dongosolo

Ma njanji atatu a axis guide njanji amatengera njanji yolowera kunja, yomwe ili ndi mphamvu yaying'ono yosunthika komanso yosasunthika, kukhudzika kwakukulu, kugwedezeka pang'ono pa liwiro lalikulu, osakwawa pa liwiro lotsika, malo olondola kwambiri, magwiridwe antchito apamwamba a servo, ndikuwongolera kulondola ndi kukhazikika kwa chida cha makina.

Ma axis atatu a servo motor amalumikizidwa mwachindunji ndi wononga mpira wolondola kwambiri polumikizira zotanuka, kuchepetsa maulalo apakatikati, pozindikira kuti palibe kutumizirana, kudyetsa kosinthika, kuyika kolondola komanso kulondola kwambiri.

Z axis servo motor yokhala ndi loko yozimitsa yokha, ikalephera mphamvu, imatha kutseka shaft yamotoyo kuti igwire mwamphamvu, kuti isazungulire, kutengapo gawo pachitetezo chachitetezo.

3. Gulu la spindle

Gulu lalikulu la shaft limapangidwa ndi opanga akatswiri aku Taiwan, olondola kwambiri komanso osasunthika kwambiri. Kukhala ndi P4 class spindle mayendedwe apadera, gulu lonse la spindle pamikhalidwe yotentha nthawi zonse, mukamaliza kuwongolera bwino komanso kuyesa kuyesa, kuwongolera moyo wonse wautumiki wa spindle ndi kudalirika kwakukulu.

Spindle imatha kuzindikira kuwongolera kwa liwiro losasunthika pama liwiro ake, spindle imayendetsedwa ndi encoder yomangidwa mkati, yomwe imatha kuzindikira momwe spindle imayendera komanso kugwira ntchito kolimba.

4. Laibulale ya mpeni

Laibulale ya chida cha robot imayikidwa pambali pa mzere. Mutu wodula umayendetsedwa ndikuyimitsidwa ndi makina a CAM odzigudubuza posintha chida. Spindle ikafika pamalo osinthira chida, chida chosinthira chida (ATC) chimamaliza kubweza mpeni ndikudyetsa mpeni.

5. Kudula dongosolo yozizira

Okonzeka ndi lalikulu otaya kuzirala mpope ndi lalikulu mphamvu thanki madzi, mokwanira kuonetsetsa kufalitsidwa kuzirala, kuzirala mpope mphamvu: 0.48kW, kuthamanga: 3bar.

Nkhope yamutu imakhala ndi ma nozzles ozizira, omwe amatha kukhala madzi kapena mpweya utakhazikika ndipo amatha kusinthidwa mwakufuna kwake. Njira yozizira imatha kuwongoleredwa ndi M code kapena gulu lowongolera.

Okonzeka ndi mfuti yoyeretsera mpweya poyeretsa zida zamakina.

6. Pneumatic system

Katatu ka pneumatic amatha kusefa zonyansa ndi chinyezi mumlengalenga kuti ziteteze kuwonongeka ndi dzimbiri za zida zamakina. Gulu la solenoid valve limayang'aniridwa ndi pulogalamu ya PLC kuonetsetsa kuti mpeni wosasunthika wa spindle, malo ozungulira ozungulira, mpeni wa spindle clamping, kuziziritsa kwa mpweya wa spindle ndi zochita zina zitha kutha mwachangu komanso molondola.

7. Makina opaka mafuta

Sitima yowongolera ndi wononga mpira zimangotenthedwa ndi mafuta ochepera apakati. Node iliyonse imakhala ndi ogawa mafuta ochulukirachulukira, omwe amayikidwa nthawi yake ndikuwerengeredwa ku magawo opaka mafuta kuti awonetsetse kuti mafuta amtundu uliwonse azitha kutsetsereka, amachepetsa kukana kukangana, kuwongolera kuyenda bwino, ndikuwonetsetsa moyo wautumiki wa wononga mpira ndi njanji yowongolera.

8. Chitetezo cha chida cha makina

Makinawa amatenga chipinda chotetezera chitetezo, chomwe sichimangolepheretsa kuphulika kwa zoziziritsa kukhosi, komanso kuonetsetsa kuti ntchitoyo ikuyenda bwino komanso mawonekedwe osangalatsa. Njanji iliyonse yolondolera ya chida cha makina imakhala ndi chivundikiro choteteza kuti tchipisi ndi zoziziritsa kuziziritsa zilowe mkati mwa chida cha makina ndikuletsa njanji yowongolera ndi wononga mpira kuti zisawonongeke ndi dzimbiri.

9. Chip kuchotsa dongosolo (ngati mukufuna)

Dongosolo lodzitetezera la Y axis limapangitsa kuti zitsulo zachitsulo zomwe zimapangidwira pokonza zigwere mwachindunji pabedi, ndipo mawonekedwe akuluakulu omwe ali mkati mwa bedi amapangitsa kuti zitsulo zachitsulo ziziyenda bwino ku mbale yachitsulo cha chain chip discharge device pansi pa makina. Mbale ya unyolo imayendetsedwa ndi chip discharge mota, ndipo tchipisi amatumizidwa ku galimoto yotulutsa chip.

Chipangizo chotumizira chip chip chili ndi mphamvu yayikulu yotumizira, phokoso lochepa, chida choteteza mochulukira, otetezeka komanso odalirika, angagwiritsidwe ntchito pazinthu zosiyanasiyana za zinyalala ndi koyilo.

Mafotokozedwe Akatundu

Zofotokozera

| Chitsanzo | Chithunzi cha VMC850L | Chigawo | ||

| Ntchito | Ntchito kukula | 1000 × 500 | mm | |

| Max. Katundu kulemera | 600 | kg | ||

| T kagawo kukula | 18 × 5 pa | mm× unit | ||

| Mtundu wokonza | Max. kuyenda patebulo - X-axis | 800 | mm | |

| Max. slide kuyenda - Y axis | 500 | mm | ||

| Max. kuyenda kwa spindle - Z axis | 500 | mm | ||

| Mtunda kuchokera kumapeto a spindle kupita kumalo ogwirira ntchito | Max. | 650 | mm | |

| Min. | 150 | mm | ||

| Mtunda wochokera pakati pa spindle kukawongolera njanji | 560 | mm | ||

| Spindle | Mpanda (7:24) | Mtengo wa BT40 |

| |

| Mtundu wa liwiro | 50-8000 | r/mphindi | ||

| Max. torque yotulutsa | 48 | Nm | ||

| Spindle motor mphamvu | 7.5/11 | kW | ||

| Spindle drive mode | Lamba wa m'mano wa Synchronous |

| ||

| Chida | Chida chogwirira ntchito | Mtengo wa MAS403 BT40 |

| |

| Kokani chitsanzo cha msomali | Mtengo wa MAS403 BT40-I |

| ||

| Dyetsani | Kusuntha mwachangu | X axis | 24 (36) | m/mphindi |

| Y axis | 24 (36) | |||

| Z axis | 24 (36) | |||

| Mphamvu yamagalimoto atatu-axis drive motor (X/Y/Z) | 2.3/2.3/3 | kW | ||

| Torque yamagalimoto atatu olamulira (X/Y/Z) | 15/15/23 | Nm | ||

| Mtengo wa chakudya | 1-20000 | mm/mphindi | ||

| Chida | Fomu ya magazini | Manipulator (HAT mwasankha) |

| |

| Njira yosankha zida | Kusankha zida zapafupi za Bidirectional |

| ||

| Mphamvu ya magazini | 24 |

| ||

| Kutalika kwakukulu kwa chida | 300 | Mm | ||

| Zolemba malire chida kulemera | 8 | Kg | ||

| Max.cutter mutu awiri | Zodzaza | Φ78 ndi | Mm | |

| Pafupi mpeni wopanda kanthu | φ120 | Mm | ||

| Nthawi yosinthira chida (chida kupita ku chida) | 1.8 (Chipewa cha Bamboo8S) | S | ||

| Kuyika kulondola | JISB6336-4:2000 | GB/T18400.4-2010 |

| |

| X axis | 0.016 | 0.016 | Mm | |

| Y axis | 0.012 | 0.012 | Mm | |

| Z axis | 0.012 | 0.012 | Mm | |

| Bwerezani kulondola kwa malo | X axis | 0.010 | 0.010 | Mm |

| Y axis | 0.008 | 0.008 | Mm | |

| Z axis | 0.008 | 0.008 | Mm | |

| Kulemera kwa makina | 4800 | Kg | ||

| Mphamvu zonse zamagetsi | 20 | KVA | ||

| Makulidwe onse (L×W×H) | 2730×2300×2550 | Mm | ||