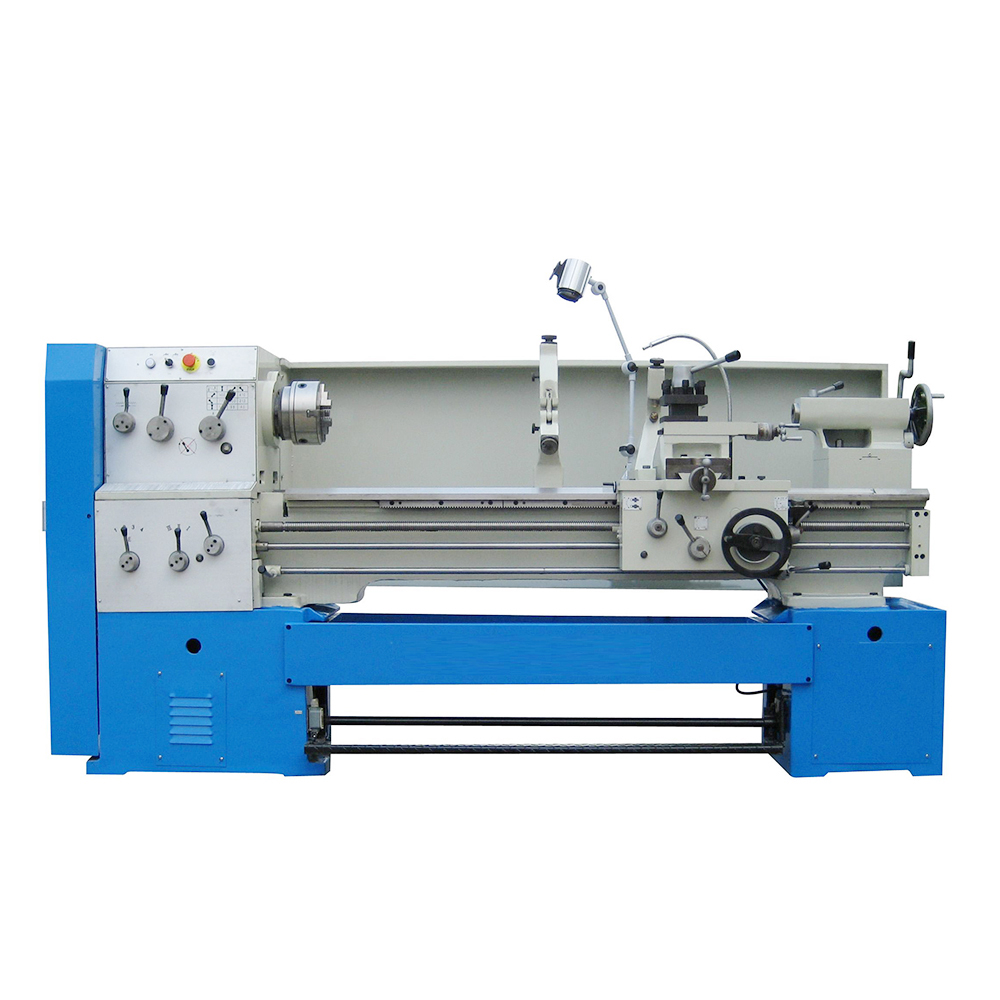

Manual Lathe Machine Ochiritsira CS6240

Mawonekedwe

Lathe iyi ili ndi maubwino a liwiro lalikulu lozungulira, kabowo kakang'ono ka spindle, phokoso lochepa, mawonekedwe okongola, ndi ntchito zonse.Ili ndi kuuma kwabwino, kulondola kozungulira kwambiri, pobowola kwambiri, ndipo ndiyoyenera kudula mwamphamvu.Chida ichi cha makina chilinso ndi ntchito zosiyanasiyana, zosinthika komanso zosavuta, zowongolera zapakati pazida zogwirira ntchito, chitetezo ndi kudalirika, kusuntha mwachangu kwa bokosi la slide ndi mbale yapakatikati, ndi chida champando wa mchira chikupanga kuyenda kupulumutsa ntchito. .Chida cha makina ichi chili ndi taper gauge, yomwe imatha kutembenuza ma cones mosavuta.Njira yoyimitsa kugunda imatha kuwongolera zinthu zambiri monga kutembenuka kwautali.

Ndizoyenera ntchito zamitundu yonse, monga kutembenuka kwamkati ndi kunja kwa cylindrical, mawonekedwe a conical ndi malo ena ozungulira ndi nkhope zomaliza.Ithanso kukonza ulusi wosiyanasiyana womwe umagwiritsidwa ntchito, monga metric, inchi, module, ulusi wa mainchesi, komanso kubowola, kubwezeretsanso ndi kugogoda.Kuwotchera waya ndi ntchito zina.

Zofotokozera

| Chitsanzo | UNIT | Chithunzi cha CS6240B | Mtengo wa CS6240C | |

| Mphamvu | Max.swinga dia.pabedi | mm | Φ400 pa | |

| Max.swing dia.in gap | mm | Φ630 ndi | ||

| Max.swinga dia.pamwamba pa masiladi | mm | Φ200 pa | ||

| Max.kutalika kwa workpiece | mm | 1000/1500/2000/3000 | ||

| Spindle | Diameter ya spindle | mm | Φ82(B mndandanda) Φ105(C mndandanda) | |

| Chophimba cha spindle bore |

| Φ90 1:20 (B mndandanda) Φ113 1:20 (B mndandanda) | ||

| Mtundu wa mphuno za spindle | no | ISO 702/II NO.8 com-lock mtundu(B&C mndandanda) | ||

| Kuthamanga kwa spindle | R/mphindi | 24 masitepe16-1600 | ||

| Spindle motor mphamvu | KW | 7.5 | ||

| Mofulumira kudutsa motoe mphamvu | KW | 0.3 | ||

| Mphamvu yamagetsi yapampope yoziziritsa | KW | 0.12 | ||

| Tailstock | Diameter ya quill | mm | Φ75 ndi | |

| Max.ulendo wa quill | mm | 150 | ||

| Msuzi wa quill (Morse) | MT | 5 | ||

| Tureti | Chida OD kukula | mm | 25x25 pa | |

| Dyetsani | Max.travel wa zida zapamwamba | mm | 145 | |

| Max.Kuyenda kwa zida zapansi | mm | 320 | ||

| X axis feedrate | m/mphindi | 50HZ:1.9 60HZ:2.3 | ||

| Z axis feedrate | m/mphindi | 50HZ:4.5 60HZ:5.4 | ||

| Zakudya za X | mm/r | 93 mitundu 0.012-2.73(B mndandanda) 65 mitundu 0.027-1.07(C mndandanda) | ||

| Z zakudya | mm/r | 93 mitundu 0.028-6.43(B mndandanda) 65 mitundu 0.063-2.52(C mndandanda) | ||

| Ma metric threads | mm | 48 mitundu 0.5-224(B mndandanda) 22 mitundu 1-14 (C mndandanda) | ||

| Inchi ulusi | tpi | 46 mitundu 72-1/8(B mndandanda) 25 mitundu 28-2 (C mndandanda) | ||

| Ma module a ulusi | pa mm | 42 mitundu 0.5-112(B mndandanda) 18 mitundu 0.5-7(C mndandanda) | ||

| Dia metric pitch threads | DP | Mitundu 45 56-1/4(B mndandanda) 24 mitundu 56-4(C mndandanda) | ||

| Kukula kwake (mm) | kutalika | 2632/3132/3632/4632 | ||

| m'lifupi | 975 | |||

| kutalika | 1270 | |||

| kulemera | Kg | 2050/2250/2450/2850 | ||